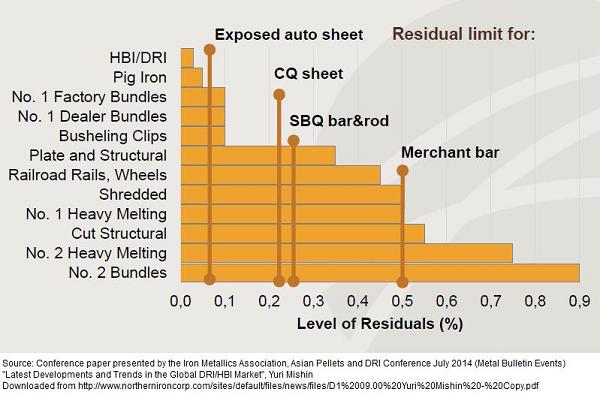

Steelmaking residuals levels from different iron unit sources

Residuals refer to 'tramp elements' such as copper (Cu) and tin (Sn), which are typically introduced into the steelmaking process in the form of unsorted or contaminated scrap and which can impair the physical and mechanical properties of steel. Less common residuals in carbon and low alloy steels include elements such as antimony (Sb), tungsten (W), cobalt (Co), nickel (Ni) and molybdenum (Mo).

For some applications such as rebar, the content of these tramp elements is not so critical. For others such as automotive body panels, residual levels must be strictly controlled. This control is often undertaken by careful scrap selection; and also through use of DRI and / or pig iron which can effectively dilute tramp element content to acceptable levels.

An analysis is shown below of the typical residual content of different sources of iron units for steelmaking. A chart illustrates the expected residual content of HBI, DRI, bundles, busheling clips, plate, rails, HMS and other common EAF raw materials.

Back to Knowledge Base Index

To contact us about metallics issues please email info@steelonthenet.com.